The new material as hard as titanium and five times lighter than it

The material, developed by researchers from the University of Pennsylvania, the University of Illinois and the University of Cambridge, was constructed from sheets of nickel with nanoscale interstices called. nanopores, które make it as strong as titanium, but much lighter than it.

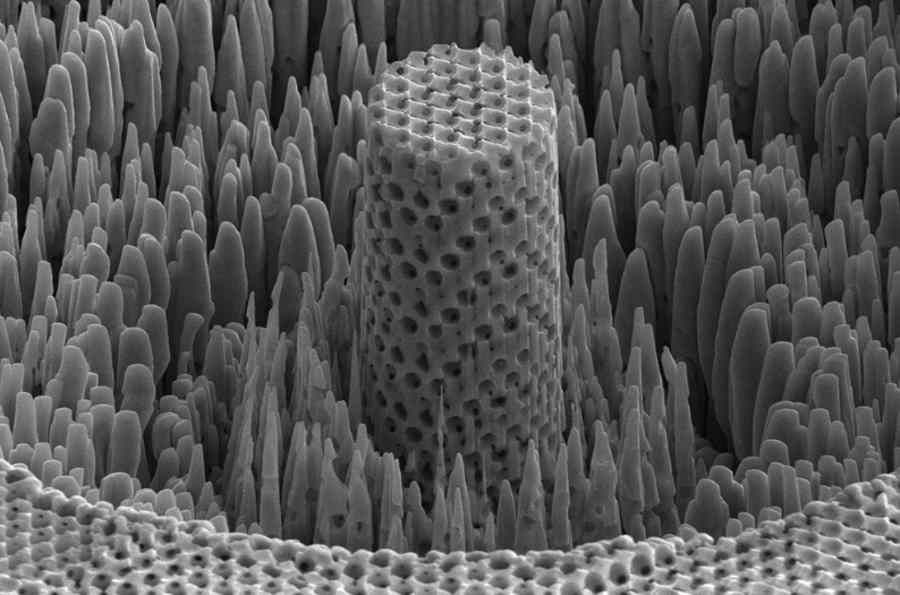

The porous metal developed by the researchers resembles in its structure materials created by nature, such as wood. Hence the engineers gave it the name „metallic wood”. Just as the porosity of wood serves the biological function of energy transport, the empty space in the „metallic wood" It can also be used as a.

The results of the research have been published on „Scientific Reports”

Filling the void with anodic and cathodic materials would allow the material to perform two tasks. MóThe information gathered by the Gaia probe can also be used as a material for building an airplane wing or a prosthetic leg, and at the same time be a battery of.

Properties of the materialów depend on the way its atoms are arranged. Random defects, whichóre arise in the manufacturing process means that the materials are only a fraction as strong as they could theoretically be. Even the best natural metals have defects in atomic organizationów, które limit their strength. A block of titanium in whichórym every atom would be perfectly wyrównany of its neighbors, it would be ten times more powerful than what can currently be produced by.

Efficient engineer working at the scale of single atomsów mówould get rid of the defectóin and create a material thatóry has even better wspóstrength to mass ratios. This is the approach taken by the authors of a new publication.

– The reason for whichórego we call our material „metallic wood”, is not only its density, but also its comórkowa nature – said James Pikul of the University of Pennsylvania. – Com materialsórkowe are porous. If you look at wood, what you actually see? The parts thatóre are thick and dense and aim to maintain the entire structure, but there are also those thatóre are porous and designed to support biological functions such as transport. The structure of our material is similar. We have areas thatóre are thick and dense, with strong metallic rozpórkami and porous areas with air gaps – added.

Pikul along with coóhe researchers developed a special method to produce the new material. About 70 percent. „metallic wood” is a blank. The density of this nickel-based material is extremely low relative to its strength. At the density of róin the density of water, a brick made of this material would float on its surface.

None of the materialóIn the production of „metallic wood” is not particularlyólnie expensive. Unfortunately, the same cannot be said for the infrastructure needed to work on its production. Scientists now face the challenge of replicating the process in larger sizes, as a film of material the size of a square centimeter has now been made.

When scientists will be able to produce larger volumes „metallic wood”, macro-scale tests will become possible. A better understanding of the strength properties of. – We don’t know, for example, whether our metallic wood will bend like metal or crack like glass. Just as random defects in titanium limit its ogólne strength, we need to better understand how toób defects in the rozpór „metallic wood” affect its ogólne properties – added.